À la carte or individualised – Jungbecker Optics gives its customers the choice. Whether a customer proposal which we cooperate with developers to make into a product, a service is requested or a catalogue item is ordered: In each case, we find an ideal solution.

This teamwork fuels synergies, the scope of which transcends the technology push. Sometimes the catalyst is external, harnessing joint efforts to forge a solution which is not only good, but perfect. When commissioned by a client, we always consider the task at hand, development efficiency and the end product itself from the customer perspective.

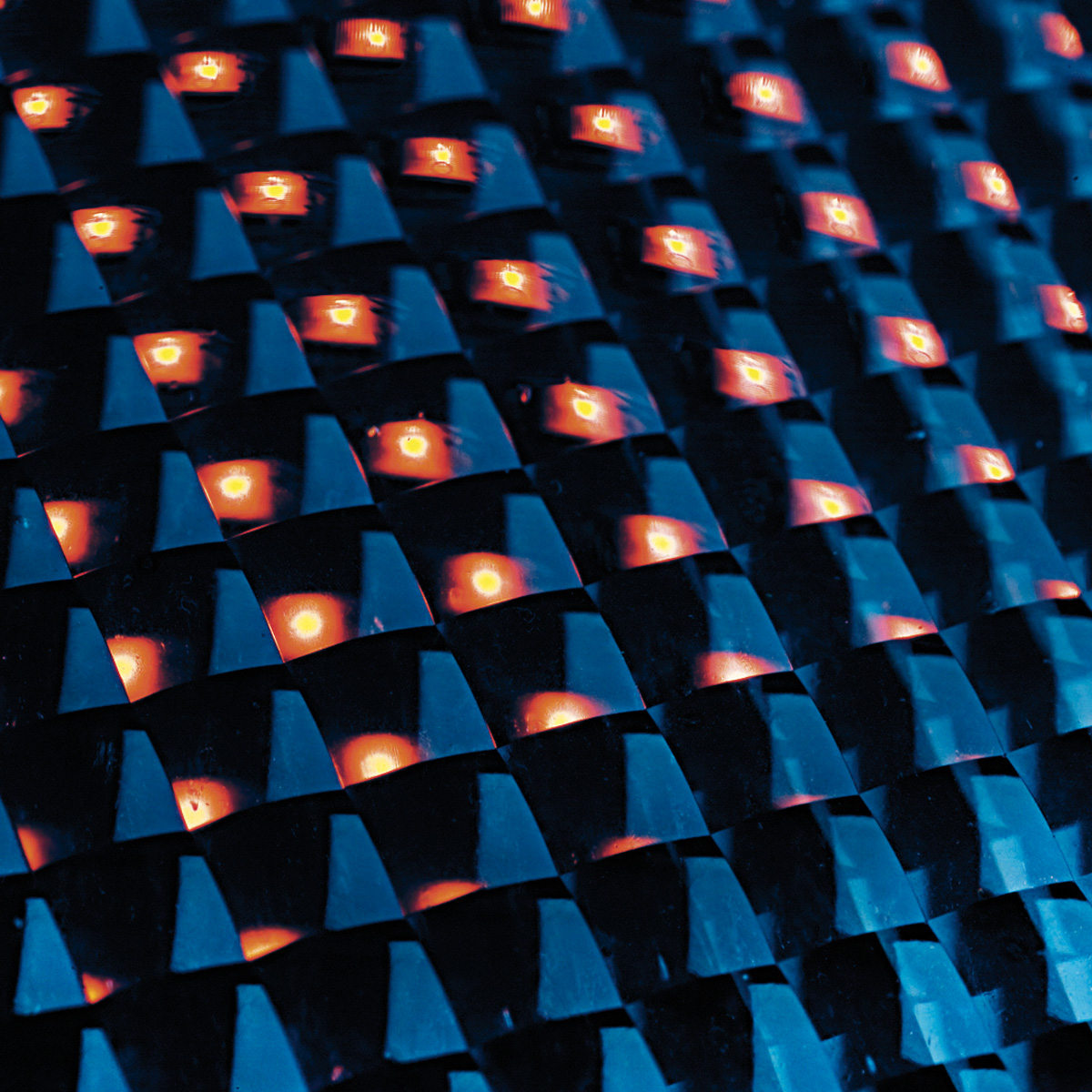

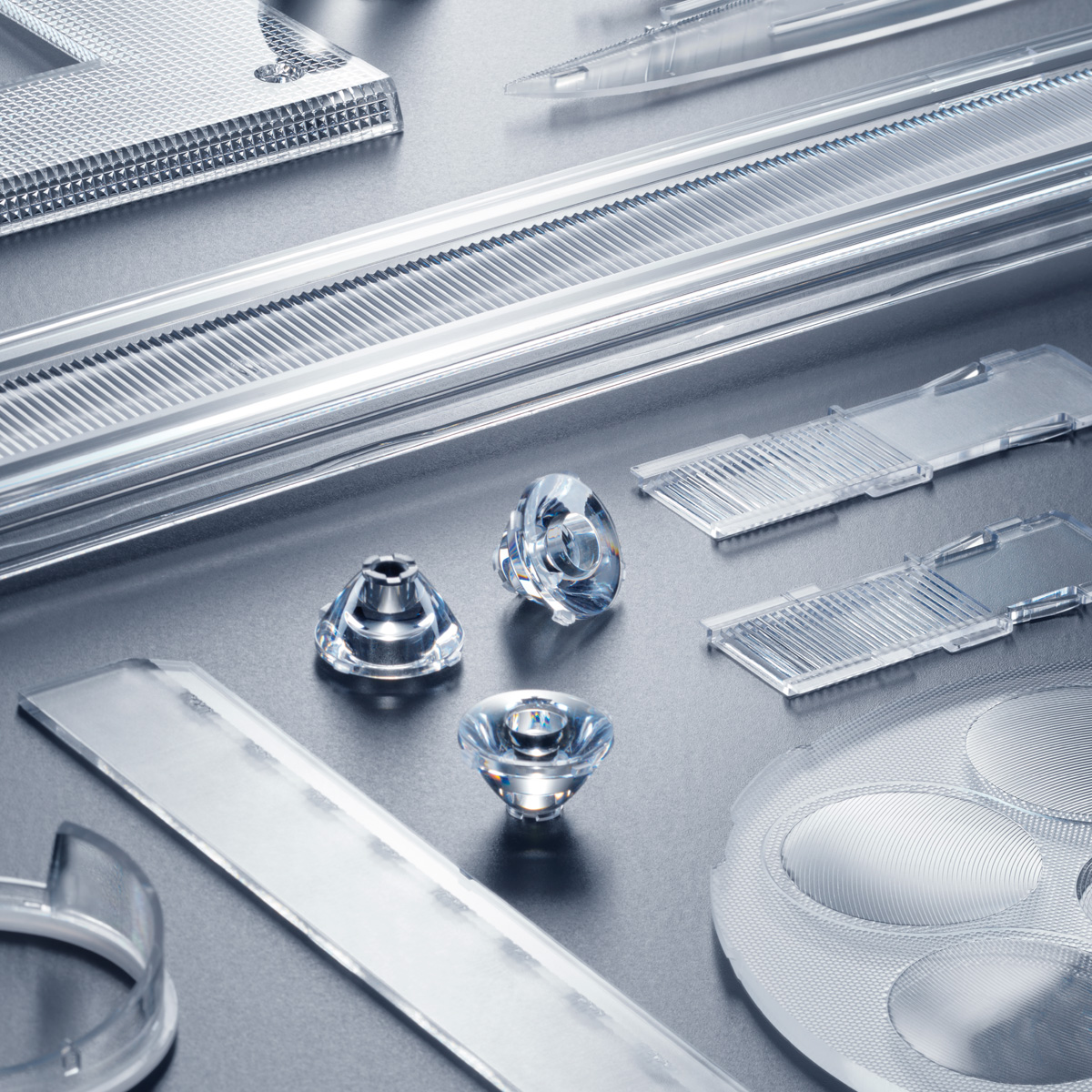

Numerous technical optical products from Jungbecker Optics tailored to individual customer specifications have been deployed in the automotive industry, medicine or science fields: including lenses, collimators and light-deflecting elements. These customised developments and production processes are key to successful small- and large-scale production. Examples where precise light direction is used include anti-collision lights installed on buildings for aviation, traffic signalling devices or lighting of vehicle dashboards. Fresnel lenses can be found in large-format projectors or lenticular lenses in 3D stereoscopy.